-

machine

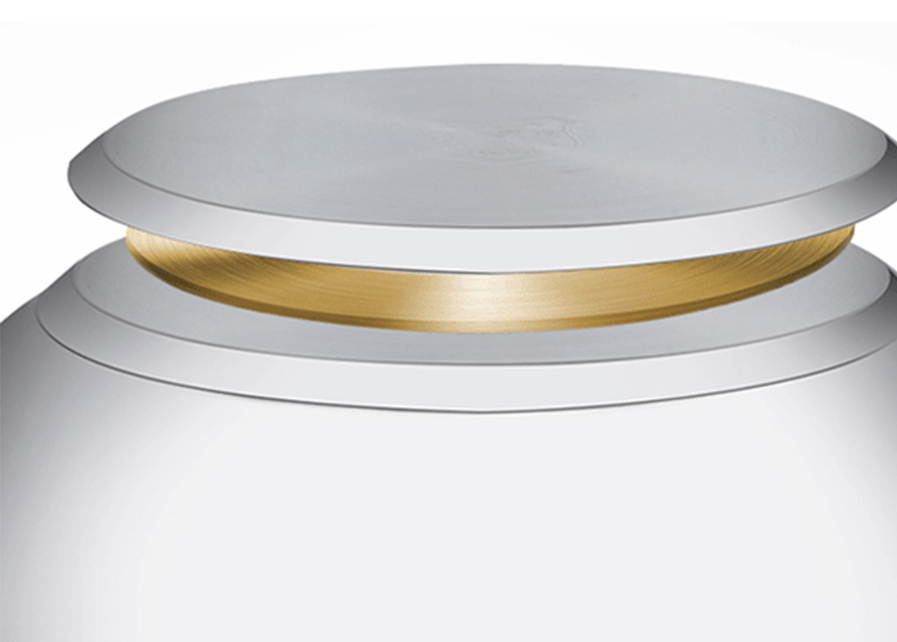

This machine mainly used for cookware and utensil (stainless steel or aluminum pan, pot, casseroles, boiler, kettle and other catering utensils) preheating before compound pan bottom pressure welding, and working together with the friction press machine, and then finish the pressure welding process of compound metal, and this process also called “bottoming”. The heating power supply and the machine are both controlled by microcomputer, and this cookware bottom heating equipment is an electric, mechanical and pneumatic integrated high-tech equipment controlled by several sets microcomputer.

It is mainly consists of three parts:

1.Induction Heating power supply.

2.Heating machine tool.

3.Water cooling system.

Features of cookware bottom induction heating machine:

1.Using high power IGBT super-audio induction heating power supply, save electricity, water saving, safety and reliability.

2.Uniform heating and good product quality.

3.Fast heating speed and high production efficiency.

4.Stainless steel surface oxidation very few.

5.Digital display of operating mode and easy maintenance.

6.Energy saving and environment protection, low failure rate.

Model: IH-4-200kw

Power : 200KW (option: 160KW, 200KW, 240KW)

Frequency: 10-40KHz

Working position: 4 working position

Heating pan bottom diameter: 70-300mm ( above can custom make)

Working area height: 350mm (above can custom make)

Working speed: 4-12pcs/min ( depend on thickness, diameter and number of working position)

Heated material:stainless steel, copper, aluminum, steel, etc.

-

Power supply Features:

1.All solid state IGBT inversion technology, high-efficient conversion.

2.Phase locking looping technology and soft switch ensure good reliability, realize power and frequency tracking automatically, stepless power adjustment.

3.Complete self-protect functions, over-current, over-voltage, over hot, water shortage, phase failure and other alarm indicator, and automatic control and protection.

4.Low energy consumption, converts up to 97.5% above of the expended energy into useful heat. energy saving 15%-30% compared with SCR induction heating equipment and other traditional heating methods.

5.Easy installation and simple operate, connect the power and water, induction coil, can be done by unprofessional person and learn to operate in a few minutes.

6.Good effect, heating fast and uniform heating temperature, Consistent product quality and less oxide layer.

7.Environment friendly, no gas needed, no open flame, no additional heating. Less pollution and noise pollutio

n which will help protect the environment, improves working conditions for your employees by eliminating smoke, waste heat, noxious emissions and loud noise.8.Safe eliminate high pressure, No thousands of volts high-pressure danger, security is very high, very safe for the operator.

9.Application flexibility, easy to change induction coils to meet various size of workpieces and request.

10.Small space occupation, light weight can beside any corollary equipment.

11.Working 24 hours continuously with 100% duty cycle, power can be instantly turned on or shut off.

12.Perfect protective circuit and cooling system (water+air),which ensure the good reliability of machine.

13.Analog display of current, and Built-in digital heat timer, very visual. digitized display with operation parameters and fault indications which can providing great convenience of operation.

-

Customer comments

Induction Heaters CatalogHigh Frequency SeriesSuperaudio Frequency SeriesUltrahigh Frequency SeriesMedium Frequency MF SeriesMedium Frequency MFS Series DSP Full Digital Induction Heating MachinesInduction Melting FurnaceHorizontal Continuous Casting MachineInduction Forging FurnaceInduction Hardening MachineInduction Brazing MachineMotorcycle Wheel Hub Brake Ring Heating MachineELectric Motor Induction HeatersMobile Handheld Induction HeatersHigh Frequency Tube WeldersWater Cooling system

IH-4-200KW

Cookware Pan Pot Bottom Heating Machine

Features of cookware bottom induction heating machine:

1.Using high power IGBT super-audio induction heating power supply, save electricity, water saving, safety and reliability.

2.Uniform heating and good product quality.

3.Fast heating speed and high production efficiency.

4.Stainless steel surface oxidation very few.

5.Digital display of operating mode and easy maintenance.

6.Energy saving and environment protection, low failure rate.