- Induction Coil

- FAQ

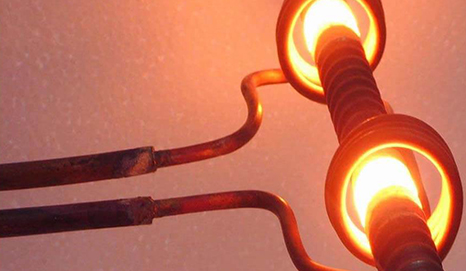

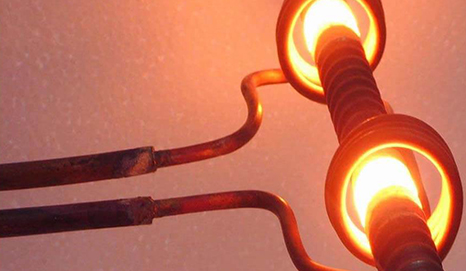

The induction coil made from copper tube, the copper tube have round copper tube and square copper tube. the water circulating in the copper tube.

The varying magnetic field required for induction heating is developed in the induction heating coil via the flow of AC (alternating current) in the coil. The coil can be made in many shapes and sizes to custom fit a specific application, single or multiple turn, helical, round or square, internal or external or other, should custom make according the shape of your workpiece and your process requirements. the coils can range from tiny coils made of copper tubing used for precise heating of extremely small parts in applications such as soldering and ferrule heating to large coil assemblies of copper tubing used in application such as strip metal heating and pipe heating.

The varying magnetic field required for induction heating is developed in the induction heating coil via the flow of AC (alternating current) in the coil. The coil can be made in many shapes and sizes to custom fit a specific application, single or multiple turn, helical, round or square, internal or external or other, should custom make according the shape of your workpiece and your process requirements. the coils can range from tiny coils made of copper tubing used for precise heating of extremely small parts in applications such as soldering and ferrule heating to large coil assemblies of copper tubing used in application such as strip metal heating and pipe heating.

The induction coil design is one the most important aspects of an induction heating system. Having the right coil, and keeping it in the best possible condition, is critical to the efficiency of your induction heating system. the coil is a custom design to give your workpiece or part the proper heating pattern and effect, maximize effieiency of the induction heating power supply’s load matching system, and to accomplish these tasks while still permitting ease of loading and unloading your part. Coil design is generally based on experience, and need testing time and again.

The induction coil design is one the most important aspects of an induction heating system. Having the right coil, and keeping it in the best possible condition, is critical to the efficiency of your induction heating system. the coil is a custom design to give your workpiece or part the proper heating pattern and effect, maximize effieiency of the induction heating power supply’s load matching system, and to accomplish these tasks while still permitting ease of loading and unloading your part. Coil design is generally based on experience, and need testing time and again.

We will provide induction coil service, the coil is miscellaneous, we tailor-made coils according your workpiece and process requirements. if you have different application can use the same machine, just replace differ induction coil to meet the different application, just tell us your workpiece and requirements, we will tailor-made and provide best coil design.

We will provide induction coil service, the coil is miscellaneous, we tailor-made coils according your workpiece and process requirements. if you have different application can use the same machine, just replace differ induction coil to meet the different application, just tell us your workpiece and requirements, we will tailor-made and provide best coil design.For more coil design and fabrication technique, please ask through e-mail, we will teach you how to make induction coil, perhaps you could make by yourself in your there.

The induction coil made from copper tube, the copper tube have round copper tube and square copper tube. the water circulating in the copper tube.

The induction coil design is one the most important aspects of an induction heating system. Having the right coil, and keeping it in the best possible condition, is critical to the efficiency of your induction heating system. the coil is a custom design to give your workpiece or part the proper heating pattern and effect, maximize effieiency of the induction heating power supply’s load matching system, and to accomplish these tasks while still permitting ease of loading and unloading your part. Coil design is generally based on experience, and need testing time and again.

The induction coil design is one the most important aspects of an induction heating system. Having the right coil, and keeping it in the best possible condition, is critical to the efficiency of your induction heating system. the coil is a custom design to give your workpiece or part the proper heating pattern and effect, maximize effieiency of the induction heating power supply’s load matching system, and to accomplish these tasks while still permitting ease of loading and unloading your part. Coil design is generally based on experience, and need testing time and again.

What is induction heating?

What is induction heating?

Induction heating is a form of non-contact heating for electric conductive materials, an alternating current flowing through a coil generates a magnetic field, placing a workpiece(electric conductive material) within the coil induces eddy currents(resistance) in the piece, generating heat as eddy current flow againest the resistivity of the material.

Induction heating is a rapid, clean, non-polluting heating form which can be used to heat all types of metal parts or change the electric conductive material’s properties. The coil itself does not get hot and the heating effect is under controlled. The solid state transistor technology has made induction heating much easier, cost-effective heating for application such as brazing and soldering, annealing, quenching, forging, melting, shirk fitting etc

What makes up a induction heating system?

What makes up a induction heating system?

Induction heating system consists of induction heating power supply, an induction coil, electrical conductive workpiece, and a water-cooling source.

Induction heating power supply that is our MF/MFS series, HF series, SF series, UF series.

An induction coil to generate the alternating magnetic field.

An electrical conductive workpiece to be heated.

A water-cooling souce, which cools the coil and several internal components inside the power supply.

The induction heating power supply sends alternating current through the induction coil, thus generating a magnetic field. When a workpiece is placed within the coil and enters the magnetic field, eddy currents are induced within the workpiece, generating pricise and localized heat without any physical contact between the induction coil and the workpiece.

What is an induction heating coil (inductor)?

What is an induction heating coil (inductor)?

The induction coil made from copper tube, the copper tube have round copper tube and square copper tube. the water circulating in the copper tube.

the varying magnetic field required for induction heating is developed in the induction heating coil via the flow of AC (alternating current) in the coil. The coil can be made in many shapes and sizes to custom fit a specific application, single or multiple turn, helical, round or square, internal or external or other, should custom make according the shape of your workpiece and your process requirements. the coils can range from tiny coils made of copper tubing used for precise heating of extremely small parts in applications such as soldering and ferrule heating to large coil assemblies of copper tubing used in application such as strip metal heating and pipe heating.

What is the importance of the induction heating coil?

What is the importance of the induction heating coil?

The induction coil design is one the most important aspects of an induction heating system. The coil is a custom design to give your workpiece or part the proper heating pattern and effect, maximize effieiency of the induction heating power supply’s load matching system, and to accomplish these tasks while still permitting ease of loading and unloading your part. Coil design is generally based on experience, and need testing time and again. you can read more about this aspect of induction coil in our services. Or ask us, we will provide you best design.

How to select the induction heating equipment?

How to select the induction heating equipment?

Two key parameters of induction heating machine, one is output power, another is frequency.

The output power determines the speed at which a workpiece can be heated. the power selection according to the workpiece’s weight, heating temperature and required heating speed.

The frequency, along with the electrical resistivity of the workpiece and relative magnetic permeability, determines the skin depth of the eddy currents induced into the workpiece. In surface heating, the power also plays an important role in skin depth. The higher the frequency, the shallower the skin depth; the lower the frequency, the deeper the penetration.

Therefore, higher frequency are more effective for heating smaller parts or parts that require shallow heat penetration, lower frequency are more effective for larger parts with deeper heat penetration requirements.

How can my proces benefit from induction heating?

How can my proces benefit from induction heating?

Induction heating can benefit your process in a number of ways. Induction heating is highly repetitive once initial adjustments are made to the power supply. Following this phase, part after part can be heated with identical results so long as the parts are introduced to the coil similary each cycle. This can also lead to better material utilization and product yield. Induction heating can reduce or eliminate the need for skilled operators in application such as brazing and soldering. The ability of induction heating to heat all parts identically lends itself to automation of the process. Induction heating can also heat the part in a highly localized fashion, which can be extremely beneficial when it is desirable or necessary to limit the heat to only a certain region of the part.

How does induction heating equipment compare to other heating sources?

How does induction heating equipment compare to other heating sources?

Induction heating is a clean form of heating which does not emit unpleasant odor. Because the current is induced directly into the part being heated, there is no radiant heating effect into a facilities ambient environment. The location of the desired heat zone can be defined to a specific area on a workpiece in order to achieve accurate and consistent results. Induction heating equipment is instantly on which means it requires no warm-up time as other conventional heating sources do. Induction heating systems are extremely energy efficient.

What are some of the other advantages to using induction heating?

What are some of the other advantages to using induction heating?

Fast cycle times - With induction heating technology, heat is produced instantly and directly within the part being heated. thus heat can be supplied as quickly as a material will permit it, eliminating typical soak times associated with radiation or convection heat technologies.

Accurate heat zone - through the development of an induction coil combined with the specification of the proper power and frequency, the can isolate or pinpoint a heat-zone, small or large without effecting surrounding areas. The result is minimal distortion in part being heated, yielding higher quality production. Additional infrared temperature control devices can also be added for further control of a process.

Consistent and repeatable&ndsp; due to the development of solid-state power supplies, the heating pattern produced by a given induction coil will be consistent from day to day, month to month. Since the induction coil is not in any contact with the part being heated and the part is being presented to the coil in a consistent fashion, the process will remain repeatable, unlike traditional flame heating or resistance heating, which have constantly changing characteristics.

Space requirements and efficiency &ndsp; due to the smaller space requirements for induction heating over many traditional heating methods, this technology lends itself to bench-top/work cell enviroments and in-line semi or fully automated process. In addtion induction heating technology is energy efficient, power consumption to crease the output power is minimal and in idle or stand-by conditions power consumption is greatly reduced since the power is only on when the system is being utilized for the intended process.

Environmentally friendly induction heating is an extremely clean heat. It does not produce harmful emissions or loud noise. It does not heat the enviroment or area outside the work coil, since that heat is only generated in the workpiece being heated. thus induction heating assists in creating more favorable working conditions.

Cheaper cost - cost go down because of shorter lead times and increased throughput. Integrated in-line induction heating means lower administration and logistics costs. Production yields go up. Swift heat cycles, precise delivery and accurate repeatability minimize waste and scrap. Energy costs go down because you heat only what you need to heat. compared with SCR induction heating equipment, 10%-30% energy can be saved. And because induction heating lets you abandon hazardous gas and open flames, you can negotiate lower insurance premiums.

Will induction heating working for my application?

Will induction heating working for my application?

Send us your workpiece drawings or photos, describe your process requirements, our experienced engineers will analyze and give you best advice.